Introduction

In industries like food storage, pharmaceuticals, biotechnology, and research, controlling temperature is critical to ensure the safety, longevity, and quality of products. A walk-in cold room chamber is a large-scale refrigeration unit designed to store products at consistent, low temperatures. These chambers are used for various purposes, from preserving perishable goods like food and beverages to housing sensitive biological materials that require stringent temperature control.

What is a Walk-In Cold Room Chamber?

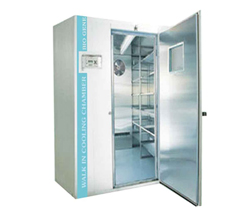

A walk-in cold room chamber is essentially a highly insulated and refrigerated space large enough for people to enter, walk around, and store products. Unlike standard refrigeration units, walk-in chambers are customizable and scalable, making them suitable for industrial or large-scale commercial use.

Cold rooms typically maintain temperatures ranging from -2°C to 10°C depending on the application. Some specialized models can also be equipped for freezing purposes, maintaining temperatures well below 0°C, ideal for frozen goods.

VISIT ALSO:- Unlocking Agricultural Potential with Giant Growth Chambers

Components of a Walk-In Cold Room Chamber

To understand how these chambers function, it’s important to look at the key components that make up a walk-in cold room:

- Insulated Panels

- The walls, ceiling, and floor of the cold room are constructed using insulated panels, usually made from polyurethane or polystyrene. These panels trap cold air inside the chamber, ensuring consistent temperatures.

- Refrigeration Unit

- The refrigeration system is the core of any cold room. It consists of compressors, evaporators, and condensers that work together to control the chamber’s internal temperature.

- Doors

- Cold room doors are specially designed to seal tightly, preventing any loss of cooled air. They are often equipped with self-closing mechanisms, magnetic gaskets, and heavy-duty handles.

- Thermostats and Control Systems

- Walk-in cold rooms come with advanced temperature control systems that allow users to monitor and adjust the internal temperature. These systems often include alarms and alerts that notify the operator if the temperature exceeds or falls below the desired range.

- Lighting

- Proper lighting inside a cold room is essential for easy navigation and ensuring worker safety. Cold rooms use LED lights, which are energy-efficient and generate minimal heat.

- Shelving and Storage Solutions

- Customizable shelving systems can be integrated to maximize storage space inside the chamber. These shelves are usually made from stainless steel or galvanized steel to prevent corrosion.

Applications of Walk-In Cold Room Chambers

Walk-in cold rooms serve a variety of industries. Here’s a closer look at some of their most common applications:

- Food and Beverage Industry

- In the food sector, cold rooms are indispensable for preserving the freshness of perishable products like fruits, vegetables, dairy, meat, and seafood. Proper temperature control in these rooms prevents spoilage, reduces waste, and helps maintain food safety standards.

- Pharmaceuticals and Biotechnology

- Temperature-sensitive materials such as vaccines, medications, and biological samples require stringent storage conditions. Cold rooms ensure that these materials are stored at optimal temperatures, preserving their efficacy.

- Agriculture and Horticulture

- Cold storage is critical for keeping harvested crops and seeds fresh before they are processed or transported. Cold rooms provide farmers and agricultural industries with a way to maintain produce quality during the off-season.

- Chemical and Research Laboratories

- Some chemicals, enzymes, and reagents need cold storage to remain stable and effective. Walk-in cold rooms are ideal for research institutions and labs where large amounts of temperature-sensitive materials are handled.

- Floral Industry

- Walk-in cold rooms are used to preserve flowers, extending their shelf life. By maintaining lower temperatures, flowers stay fresh longer, which is crucial for florists and the floral industry.

- Hospitality

- Hotels, restaurants, and catering services use cold rooms to store large quantities of food, helping maintain the quality and safety of the items served to guests.

Benefits of Walk-In Cold Room Chambers

- Customizable and Scalable

- Walk-in cold rooms can be customized to fit the specific needs of a business. Depending on the size of the operation, these chambers can be designed to accommodate a small storage space or cover a large area for bulk storage.

- Energy Efficiency

- Modern cold room chambers are designed to be energy-efficient. With the use of high-quality insulation, advanced refrigeration technologies, and LED lighting, these rooms consume less power while maintaining consistent temperatures.

- Temperature Precision

- With digital controls and monitoring systems, the temperature inside a cold room can be set and maintained with high precision. This is particularly beneficial for industries where even minor temperature fluctuations can lead to product degradation.

- Durability

- Cold rooms are built to withstand industrial use. The materials used for construction, such as stainless steel and heavy-duty insulation, ensure the chamber remains functional for years without requiring frequent maintenance or repairs.

- Compliance with Industry Standards

- Industries like food and pharmaceuticals have strict regulatory requirements for product storage. Walk-in cold rooms are designed to meet ISO, HACCP, and FDA guidelines, ensuring compliance with health and safety standards.

- Safety Features

- Walk-in cold rooms are equipped with safety features such as emergency release doors, which allow someone inside to exit in case they are accidentally locked in. Additionally, alarms alert operators if the temperature deviates from the set range.

Key Considerations When Installing a Walk-In Cold Room Chamber

When planning to install a walk-in cold room, it’s important to consider the following:

- Location and Space

- Ensure the cold room is placed in a location that can support its weight and size. Adequate ventilation is necessary for the refrigeration system to function efficiently.

- Capacity and Usage

- The size of the chamber should be based on the volume of products that will be stored. Overloading a cold room can reduce its efficiency and cause temperature fluctuations.

- Energy Efficiency

- Opt for a cold room that comes with energy-saving features such as better insulation, energy-efficient refrigeration units, and LED lighting.

- Maintenance and Support

- Cold rooms require regular maintenance to ensure they continue running efficiently. Choose a supplier that offers maintenance packages and 24/7 support.

- Cost

- The cost of installing a walk-in cold room varies depending on the size, materials, and technology used. It’s essential to balance the initial investment with the long-term benefits and cost savings in energy and maintenance.

VISIT ALSO:- Innovations in Insect Growth Chambers for Enhanced Entomological Research

Conclusion

Walk-in cold room chambers are a vital component for industries that rely on temperature-controlled storage. From maintaining food freshness to ensuring the integrity of pharmaceutical products, these chambers offer a versatile and efficient solution for modern businesses. With customizable options and advanced technology, a well-designed walk-in cold room can significantly enhance the operations of industries that require large-scale refrigeration solutions.