In today’s fast-paced manufacturing landscape, precision and versatility are key to staying ahead of the competition. Fiber laser engravers, an advanced technology in the world of laser marking, have become indispensable tools for achieving exceptional quality and efficiency. This article explores the advantages of fiber laser engraver, their applications, and why they are essential for modern manufacturing processes.

What is a Fiber Laser Engraver?

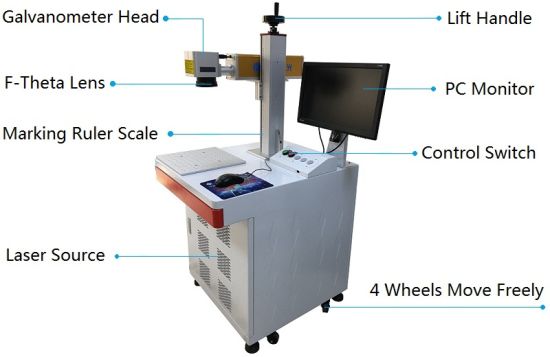

A fiber laser engraver utilizes a solid-state laser to create detailed markings and engravings on various materials. Unlike traditional lasers that use gas or CO2, fiber lasers use a doped fiber optic cable as the laser medium. This technology enables high precision and efficiency, making it ideal for various industrial applications.

Key Benefits of Fiber Laser Engravers

- High Precision and Quality

Fiber laser engravers offer unmatched precision and clarity. The focused beam produced by the fiber laser ensures that markings are sharp and detailed, which is crucial for industries requiring high-quality engravings, such as electronics, aerospace, and medical device manufacturing.

- Versatility Across Materials

One of the standout features of fiber laser engravers is their ability to mark a wide range of materials, including metals, plastics, ceramics, and even some types of glass. This versatility makes them a valuable asset in diverse industries, from automotive to consumer goods.

- Durability and Longevity

Fiber lasers are known for their durability and low maintenance requirements. The technology is designed to withstand harsh manufacturing environments and continuous operation, resulting in reduced downtime and lower operational costs.

- Speed and Efficiency

Fiber laser engravers operate at high speeds, which enhances productivity and reduces production times. The rapid marking capabilities make them suitable for high-volume production runs, ensuring that businesses can meet tight deadlines without compromising on quality.

- Cost-Effectiveness

While the initial investment in fiber laser technology can be significant, the long-term benefits are substantial. The low maintenance costs, minimal consumables, and reduced waste contribute to a lower total cost of ownership over the machine’s lifespan.

Applications of Fiber Laser Engravers

- Electronics and Semiconductor Manufacturing

In the electronics industry, fiber laser engravers are used for marking serial numbers, barcodes, and other identifiers on components. The precision and readability of the markings are critical for quality control and traceability.

- Automotive Industry

Fiber lasers play a crucial role in the automotive sector by providing permanent markings on parts and components. These markings help in tracking and verifying components throughout the supply chain.

- Medical Devices

The medical device industry benefits from fiber laser technology due to its ability to create clean and precise markings on surgical instruments and implants. The ability to engrave detailed information ensures compliance with regulatory requirements.

- Consumer Goods

For consumer goods, fiber laser engravers are used to personalize products such as jewelry, gifts, and promotional items. The high level of detail achievable with fiber lasers enhances the appeal and uniqueness of these products.

Choosing the Right Fiber Laser Engraver

When selecting a fiber laser engraver, consider factors such as the size of the work area, the types of materials you will be working with, and the specific features required for your applications. Additionally, investing in a reliable and reputable supplier can ensure that you receive quality support and service.

Conclusion

Fiber laser engravers represent a significant advancement in laser marking technology, offering unparalleled precision, versatility, and efficiency. As industries continue to demand higher quality and faster production times, fiber lasers will remain a crucial tool in achieving these goals. Embracing fiber laser technology can give businesses a competitive edge by enhancing product quality, reducing costs, and improving overall operational efficiency.