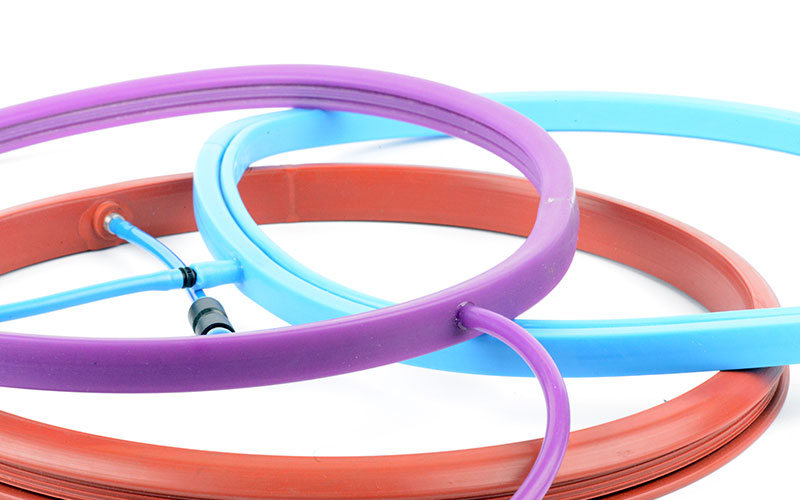

Inflatable gaskets and seals are the distinct solutions for sealing and joining requirements, which are quite progressive with flexibility, muscularity, and reliability. These inflatable solutions include flexible inflatable gaskets and seals manufactured from elastomeric material that may be inflated by either air or fluid to achieve a pressure fit. These are quite adaptable and easily conform to an uneven shape to be used for several applications across aerospace, automobiles, and construction. This seal has high pressure and temperature capabilities as well as being corrosion and chemical resistant which makes inflatable gasket and seals long lasting and highly dependable. They are also reusable, easy to install, and require little or no maintenance and inspection. These inflatable solutions act as gaskets and connectors for pipes and tubes, flanges, enclosures, panels and doors, and electrical and electronic parts, among others. Influenced by their functions and advantages, inflatable gaskets and seals become low-cost and high-performance sealing elements loved by engineers and manufacturers. They are very useful, and because of this, they are part of many other industries, guaranteeing a safe and strong closure in a given setting.

Top 3 Benefits of Inflatable Gaskets and Seals

1.Flexibility and Adaptability

- Adapts to irregular curves for a firm fitting:

In fact, inflatable gaskets and seals can be adapted to irregular surfaces such that they offer a very firm seal in areas where normal gaskets and seals cannot. This is especially helpful in cases where it is difficult to clean irregular surfaces, surfaces with pores, and such types.

- Flexible in its shape and size, with reference to its function :

Flexible gaskets and seals such as inflatable are in a position to fit and compress into various forms, thus making them accessible to different employment. They could be applied to the round windows and the, square and other forms of complex shape, and their sizes and dimensions are selectable.

- Make certain that the seal remains uniform on surfaces that are irregular or dissimilar:

Inflatable gaskets and seals guarantee that the seal will always be as smooth as possible, even where the surfaces are different in some way. This is done through the versatility of the product in relation to its ability to mold itself with the application’s surface roughness and the size it is being applied.

- Wide to accommodate Thermal Expansion and Contraction:

The inflatable gaskets and seals can expand and contract owing to the shifts in temperature; thus, the seal is not compromised in the process. This is more so in industries like the space industry, car manufacturing, and the chemical sector, where temperature fluctuations are dramatic.

2.Easy Installation

- Fast installation:

The inflatable gaskets and seals can be easily inflated by air or a fluid; this means that the installation process will be fast and will not take much time; thus, the time taken will be less. This allows for the rapid formation of a secure seal, which normally would take a number of minutes, making it ideal in an application where time is of the essence.

- Not very time consuming:

In contrast, the inflatable gaskets and seals do not require rigorous process preparation and particular tools for working. This makes it quite easy as compared to other LMS and there is no need to purchase more equipment or specialized training.

- Decreased expense on labor and time consumption:

Due to the ability of inflatable gaskets and seals to be installed easily and quickly, the amount of work that needs to be done reduces greatly in the long run, hence saving cash on labor. Due to the fast inflation of the seals and the lack of need for any special tools, the installation can be done faster, which will lead to higher production rates and lower labor costs.

- Convenient:

There are inflatable gaskets and inflatable seals with a feature that can be installed easily in limited areas or small spaces due to its materials’ characteristics. The three models are allowed to be installed in narrow spaces due to their mechanisms which do not require disassembly or the use of special equipment for installation.

3. Reliability

- Constant Effective Seal:

Inflatable gaskets and seals offer a constant, effective seal in an application where the reliability and performance of the product are paramount, irrespective of the conditions encountered. Because of their ability to seal at a wide range of temperatures and pressures, they are ideal for applications where leakage simply cannot be tolerated.

- Tight seal, even under the most extreme circumstances:

The inflatable gaskets and seals primarily utilize elastomeric materials that can withstand high temperatures and pressure together with the capability of withstanding aggressive chemicals. These materials are selected to choose a material that will be able to function in severe conditions and retain its sealing properties.

- Easy to add or remove:

These gaskets and seals come in an inflatable form, which means that one can easily make adjustments as the need arises, as this is applicable when the seal is still in use. These properties allow them to respond to such changes in temperature, pressure, or other conditions, for that matter.

- Used in applications that cannot allow loose or spillage:

Inflatable gaskets, rubber diaphragms and seals are trusted in industries where downtime or leakage cannot be tolerated, such as inflatable gaskets and seals are trusted in industries where downtime or leakage cannot be tolerated, such as:

- Aerospace

- Automotive

- Chemical processing

- Oil and gas

- Power generation

The Bottom Line

Inflatable gaskets and inflatable seals are superior sealing products that are flexible, easy to install, trustworthy, and reusable. Flexibility and a high level of resistance to pressure are characteristics of materials that can be successfully applied in critical conditions. They also require low levels of maintenance and are not affected by corrosion hence making them economical and effective. The inflatable gaskets and seals are suitable for application in different industries such as aerospace, automotive, and construction because these seals provide a perfect seal with no chance of leakage in extreme conditions. These qualities set the them as a valuable resource for engineers and manufacturers whose work includes sealing that can otherwise prove to be a time-consuming and expensive process.