Lobe pumps are a type of positive displacement pump commonly used in the chemical processing industry. These pumps play a crucial role in ensuring the efficient and precise movement of fluids within various applications, particularly where consistency, accuracy, and cleanliness are critical. As industries increasingly demand higher levels of precision and reliability, the role of lobe pump technology has grown significantly. In this article, we will explore the essential features of lobe pumps, their applications in chemical processing, their advantages over other types of pumps, and the latest technological advancements that enhance their performance.

Understanding Lobe Pump Technology

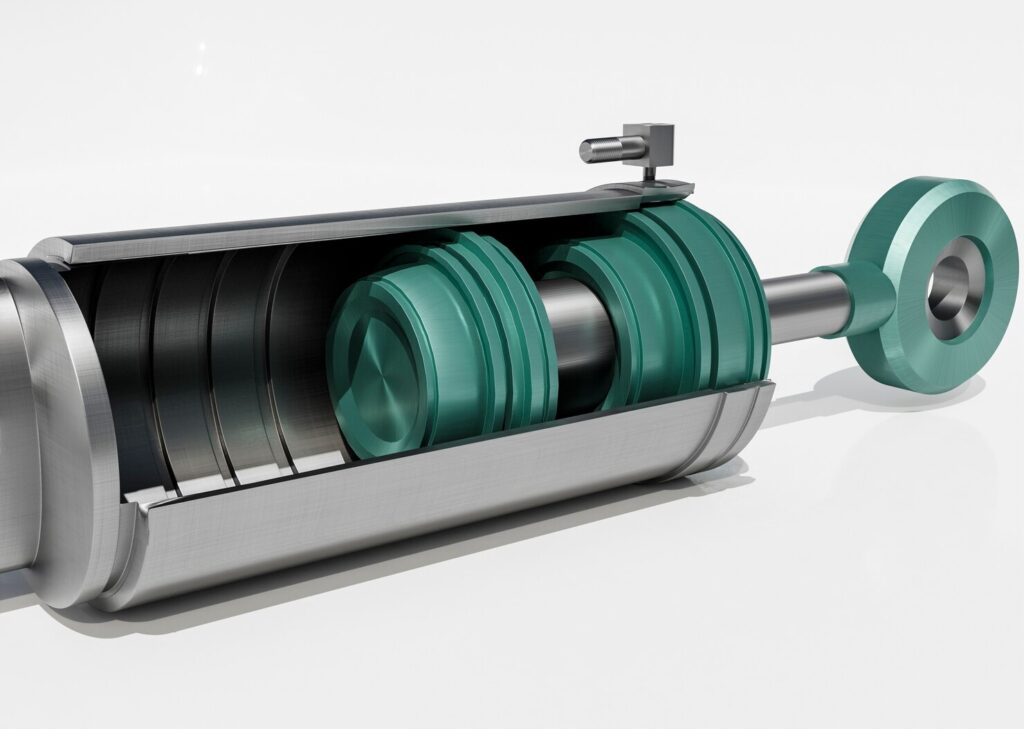

Lobe pumps are a type of rotary positive displacement pump, known for their distinctive rotor design. These pumps utilize two or more rotating lobes inside a casing to move liquids or slurries. The lobes rotate in such a way that they trap the liquid between the rotor and the pump casing, creating a continuous flow of fluid. The movement of the lobes ensures that the fluid is transferred with minimal shear, making them ideal for handling delicate, shear-sensitive fluids.

One of the primary reasons lobe pumps are preferred in chemical processing is their ability to maintain a consistent flow rate. This precision is crucial in applications where the exact quantity of fluid needs to be controlled, such as in mixing or dosing operations. The ability to accurately measure and control the flow of chemicals reduces the risk of process variability and ensures that operations run smoothly and efficiently. Additionally, the simplicity of the lobe pump design makes maintenance relatively easy, contributing to reduced downtime and long operational lifespans.

Key Applications of Lobe Pumps in Chemical Processing

Lobe pumps find widespread use in the chemical processing industry, particularly in applications where consistent, reliable fluid transfer is essential. They are commonly employed in the transportation of viscous, abrasive, and shear-sensitive fluids. For instance, in the food and beverage sector, lobe pumps are used to move liquids like sauces, syrups, and oils, which require precision and minimal disruption to their consistency. Similarly, in the pharmaceutical industry, lobe pumps are crucial for moving active ingredients and chemical formulations without compromising their quality.

Another important application of lobe pumps in chemical processing is in the handling of slurries and solids-laden fluids. These pumps can effectively transfer viscous slurries, making them ideal for industries such as mining, wastewater treatment, and petrochemicals. The ability of lobe pumps to handle a wide range of fluids, from thin liquids to thick, abrasive slurries, allows them to be used in diverse applications where other pump types might struggle. This versatility ensures that lobe pumps remain a valuable tool in optimizing chemical processing operations.

Advantages of Lobe Pumps in Precision Chemical Processing

Lobe pumps are renowned for their ability to deliver precise and consistent flow rates, which is essential in chemical processing. This precision ensures that the exact amount of fluid is transferred, reducing wastage and improving overall process efficiency. Unlike centrifugal pumps, which experience fluctuating flow rates based on system pressure, lobe pumps maintain a constant flow regardless of the pressure or viscosity of the liquid being pumped. This characteristic makes lobe pumps especially beneficial in processes that require exact measurements and controlled dosing.

In addition to their accuracy, lobe pumps offer several other advantages that enhance their role in chemical processing. For example, their design allows for a gentle pumping action, which minimizes shear forces. This is particularly important when pumping shear-sensitive fluids, such as emulsions, suspensions, or fragile chemical formulations, as excessive shear can alter the composition and quality of the product. Furthermore, lobe pumps are capable of handling fluids with varying viscosities, from thin liquids to thick pastes, without compromising their performance. This versatility makes them indispensable in industries that require a high degree of flexibility in their pumping solutions.

Technological Advancements in Lobe Pump Design

The design of lobe pumps has evolved significantly over the years, with various technological advancements aimed at improving performance, efficiency, and reliability. One of the key advancements is the development of more durable and corrosion-resistant materials for the pump’s components. Modern lobe pumps are often constructed with materials such as stainless steel, which provide superior resistance to chemical corrosion and wear. This makes them well-suited for demanding chemical processing applications where the pumps are exposed to harsh chemicals and high temperatures.

Another significant development in lobe pump technology is the improvement of sealing systems. Traditional mechanical seals have been replaced with more advanced, hygienic seal designs that reduce the risk of contamination and improve overall pump performance. These seals also help to reduce maintenance costs by extending the lifespan of the pump and reducing the frequency of repairs. Additionally, the integration of advanced monitoring systems in modern lobe pumps allows for real-time performance tracking, which helps operators to identify potential issues before they lead to costly downtime.

The Future of Lobe Pump Technology in Chemical Processing

Looking ahead, lobe pump technology is expected to continue evolving to meet the increasing demands of the chemical processing industry. One of the key trends in the future of lobe pumps is the integration of automation and smart technology. Automated lobe pumps, equipped with sensors and real-time monitoring systems, can provide operators with valuable insights into pump performance, helping to optimize operations and reduce downtime. These advancements in pump intelligence are expected to lead to more efficient and cost-effective chemical processing operations.

In addition to automation, there is also a growing focus on sustainability within the chemical processing industry. Lobe pump manufacturers are exploring ways to reduce energy consumption, improve efficiency, and minimize waste. Future innovations in lobe pump technology may include more energy-efficient designs and the use of eco-friendly materials to make pumps more sustainable. As the demand for precision, reliability, and sustainability continues to rise, lobe pumps will undoubtedly play a central role in advancing the efficiency and sustainability of chemical processing operations.

Conclusion

Lobe pump technology is a cornerstone of precision in chemical processing, offering a reliable and efficient means of transferring a wide range of fluids with accuracy and minimal shear. Their versatility, durability, and ability to handle both viscous and shear-sensitive fluids make them indispensable in industries such as food and beverage, pharmaceuticals, and chemicals. With ongoing advancements in materials, sealing technologies, and automation, lobe pumps are set to continue playing a key role in enhancing the efficiency, reliability, and sustainability of chemical processing operations. As the industry evolves, the adoption of lobe pumps will remain essential for companies seeking to optimize their processes while maintaining the highest standards of quality and precision.