Aluminum also enjoys its application in construction to some extent because it is strong, universally preferable, and can also withstand corrosion to some degree. By the same token, aluminum profiles are instrumental in multiple architectural purposes. These profiles are transforming the outlines of structural frameworks up to the ornaments and other decorations. In the following article, we will uncover why aluminum profiles are used, what advantages come with using aluminum profiles, and how they are incorporated in different industries.

What Are Aluminum Profiles

Extruded aluminum shape is a category of aluminum profiles intended mainly for construction and manufacturing applications. Extrusion is a technique whereby aluminum is forced through a die to take a particular cross-sectional form and is then in long lengths, which can be cut to size and shaped. They are available in different dimensions and cross-sectional forms, including T-slots, angles, and channels, as well as others with more complicated outlines.

Primarily due to their thin but strong structure, aluminum profiles are perfect for usage where weight is critically important, but at the same time, the strength cannot be compromised. In welding, automotive, or any other industry, aluminum profiles have strength and flexibility in equal measure.

Here are the advantages associated with aluminum profiles, hence making them appropriate for custom homes.

Such aluminum profiles are widely known for diverse advantages, and therefore, they are valued by engineers and architects. Here are some of the main advantages:

- Lightweight: Aluminum is lighter than the majority of the other metals, including steel. This also makes aluminum profiles manageable, transportable, and very easy to fix, minimizing the construction costs tremendously and the time taken in construction.

- Corrosion Resistance: Compared to other metals, aluminum forms a passive layer of oxide naturally, which does not allow itself to be corroded. This property makes the aluminum profiles ideally suited for outdoor applications, including the applications in windows and façade systems.

- High Strength-to-Weight Ratio: In simpler terms, aluminum profiles are associated with being lightweight but have the best strength as a material. This makes them ideal for structural use on applications where materials ought to bear load without much addition of weight.

- Aesthetic Appeal: The aluminum profiles may be anodized or given other surface treatments, thus giving the architects the possible finishes to use in projects. Aluminum too has other advantages, such as being shiny and, in the form of buildings, giving out a classy and elegant look.

- Thermal Efficiency: In window and door systems, aluminum profiles can easily be enhanced with thermal breakages, as this makes interiors warmer in winter and cooler in summer.

Some of the uses of aluminum profiles in construction are:

Aluminum profiles can be applied in various fields, although their usage in the construction industry is exceptionally remarkable. Some of the common uses include:

- Aluminium Profiles For Windows Frames: Aluminum, because of its strength and sustainability, has become quite common in the production of window frames. Those give a slim, modern appeal while enabling serious glass proportions for optimal amounts of natural light.

- Doors and Curtain Walls: Frequently, aluminum profiles are employed for door construction and design of curtain walls in tall structures. Due to their lightweight, they are suited for big structures where the weight of the structure is a material consideration.

- Structural Glazing: The ‘Structural Glazing system’ features aluminum framing members to support extensive clear-glazing infill in business structures, which gives an apparent all-glass facade.

- Balustrades and Railings: Aluminum profiles are especially applied to make balconies, staircases, and terraces balustrades and railings. They do not corrode, and hence they can easily be used outdoors.

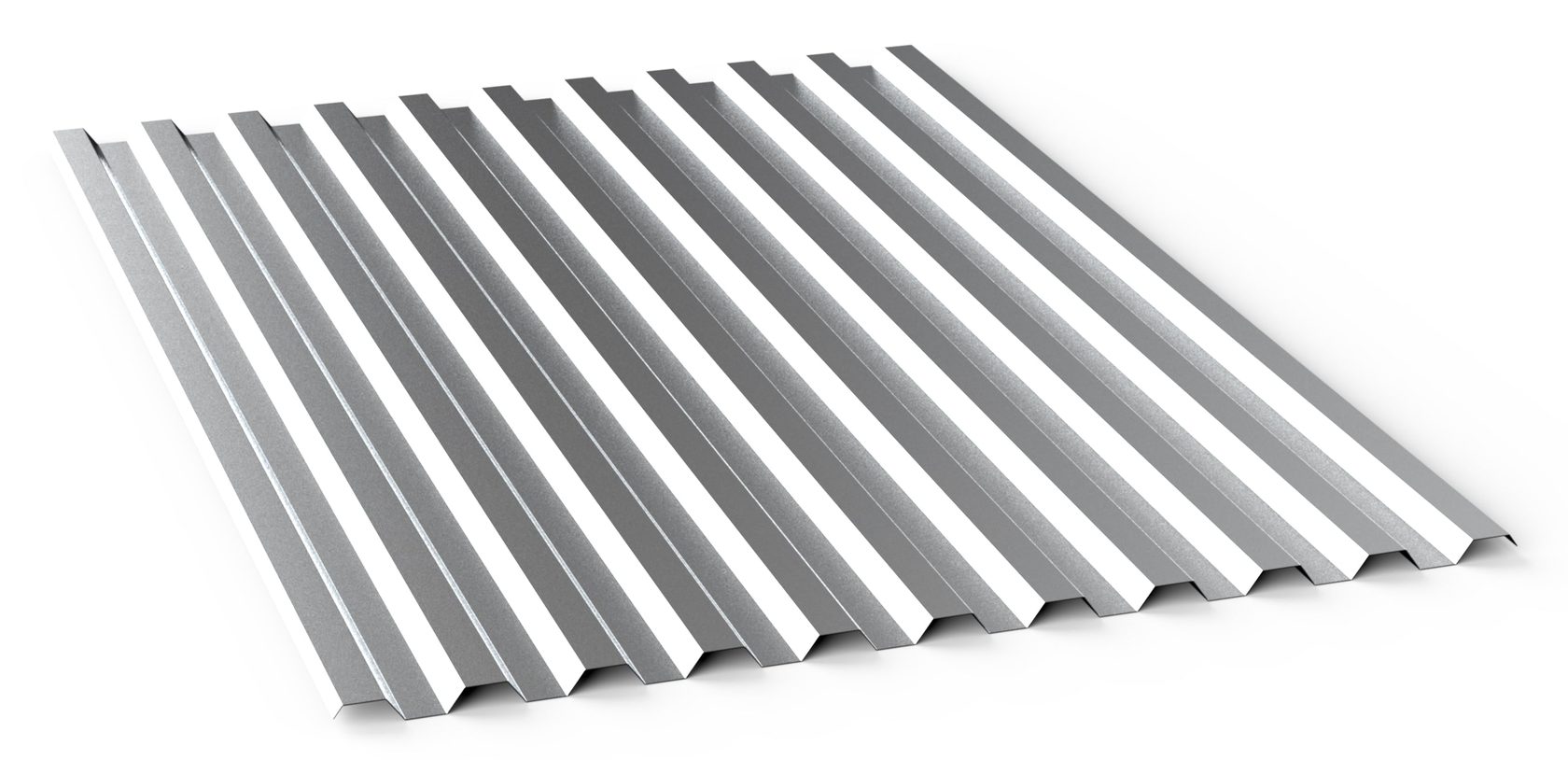

- Roofing and Cladding: Aluminum profiles in roofing and cladding offer protection and also aesthetics; in cladding, aluminum profiles are commonly used in roofing and walling. They relieve the building structure from most of the loads due to their lightweight.

Customization of Aluminum Profiles

Aluminum profile activities would be among the most beneficial because of the flexibility in style that would allow for a project-based production. Extrusion provides the ability to generate a formation of specific shapes that would suit a certain use. Aluminum profiles can also be modified in terms of size, shape, or surface by the architectural design or structural requirements of a particular construction.

Most aluminum profiles are treated by anodizing, powder coating, or painting to give both the advantages of surface protection and ornamentation. For instance, anodized profiles, though slightly more expensive, offer improved corrosion protection and may be produced in a range of colors.

The Use of Aluminum Profiles in Modern/Eco Construction

The topic of sustainability is a hot issue for construction, and aluminum profiles are assisting in its implementation. Aluminum has properties that make scrap materials reusable; hence, the resources used in extracting the new aluminum are saved. Thirdly, aluminum-made structures have a long life span, and hence, it make the structures last long without needing to be replaced frequently.

Energy efficiency is also another aspect of green building construction. Cladding can be designed using aluminum profiles that have incorporated breaks to enhance the insulation of windows and doors. This results in lower utilization of energy in the buildings, which is an advantage both to the environment and the expenses per energy.

Selecting the Right Aluminum Profile for Your Project

- Application: Find out whether the profile will be utilized for load-bearing, doors and windows, or ornamental purposes. The kind of profile will depend on the specific application that is being created.

- Load-Bearing Requirements: Given the strength ratio of the project, it is possible to find suitable piles and columns. In cases of high loads in the profile, it is necessary to use a thicker profile with additional stiffeners.

- Environmental Conditions: For exterior uses, make sure that the aluminum profile has the right surface treatment to enable it to endure conditions such as humidity, rainfall, or high temperatures.

- Aesthetic Preferences: When it comes to the finishing of the building, choose a color that would blend well with the remaining architecture. Anodized or powder-coated profiles can be chosen to the required color range.

- Thermal Performance: In extreme temperatures, go for the aluminum profiles that have enhanced thermal breaks to enhance the insulation and thereby reduce energy consumption.

Conclusion

Aluminum profiles have become incorporated into the construction industry because the product is strong, durable, and imbued with an aesthetic characteristic. They are applied in various fields, with aspects touching windows, frames, and structural support, among other aspects, thus offering required solutions to modern buildings. They can be recycled, and the details of their usage can be tuned in a way that optimizes energy usage, thus making it a material of value in sustainable construction. As green building practices are adopted as a norm, aluminum profiles are poised to be a significant influence on progressive architectural morphology in the future.

Through aluminum profiles, one can work on a house project, business projects, or even industrial projects to make the most beautiful designs. When selecting the aluminum profile for windows or many other applications, it is important to first identify the specific needs of the application to guarantee durable and efficient service.