Feeding the Future: Breakthrough Technologies Transforming Alternative Protein Processing Equipment

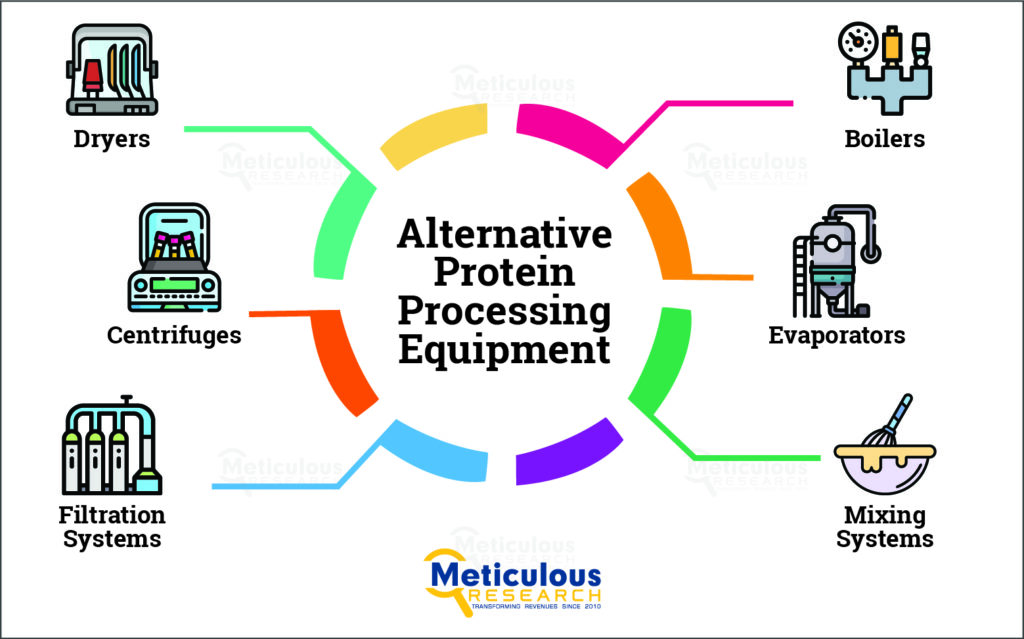

industry is at the forefront of a culinary revolution, responding to the rising consumer interest in plant-based diets and sustainable food options. This sector relies heavily on advanced equipment, including dryers, centrifuges, filtration systems, mixing systems, evaporators, boilers, grinders, and screw presses, each fulfilling specific roles in the processing of protein ingredients. The diversity in equipment types reflects the complexity of transforming raw materials into high-quality, market-ready protein products.

Download sample Report : https://www.meticulousresearch.com/download-sample-report/cp_id=5342

Innovative solutions are paramount in this industry, particularly those that facilitate automated processing. Manufacturers are increasingly focused on developing equipment that ensures faster food processing, improves cleaning efficiency, reduces labor costs, enhances energy efficiency, and minimizes both capital and maintenance costs. This demand for advanced offerings is pushing manufacturers to invest in research and development to meet these evolving requirements and enhance the quality of their customers’ products.

An exemplary innovation in this field is the PerMix Vacuum Sigma Mixer & Extruder, unveiled by PerMix (China) in January 2023. Designed specifically for plant-based protein processing, this versatile machine combines blending, mixing, extruding, and forming into a single unit, significantly boosting production capacity. By minimizing manual labor and maximizing energy efficiency, the PerMix solution eliminates the need for multiple systems, presenting a cost-effective alternative for manufacturers.

ANDRITZ AG (Austria) has also made significant contributions with its VDC fluid bed drying-cooling system, which can operate as a dryer, cooler, or both. This adaptability not only enhances operational safety under various conditions but also shortens processing times compared to traditional methods. Such advancements are crucial for manufacturers seeking to streamline their production processes and respond swiftly to market demands.

In Denmark, SiccaDania A/S offers the SD PreVap system, which integrates membrane filtration with evaporation techniques. This innovative approach addresses customer needs while effectively reducing capital expenditures, showcasing how equipment advancements can drive both efficiency and cost-effectiveness in production.

Buy Now : https://www.meticulousresearch.com/Checkout/26769470

As the alternative protein industry matures, the importance of automation and digital transformation continues to grow. A decade ago, product evaluation methods were primarily reliant on human sensory panels, a practice that was both costly and imprecise. The introduction of analytical tools has significantly improved the ability to understand and quantify the functional attributes of alternative proteins in comparison to conventional sources such as meat, eggs, and dairy.

These technological advancements have led to enhancements in the texture and mouthfeel of alternative protein products, improving their acceptance in the market. The implementation of manufacturing execution systems (MES) has emerged as a game-changer for operational efficiency, enabling manufacturers to manage ingredient tracking, recipe management, and quality assurance seamlessly.

By utilizing MES, companies can gain greater visibility into their production processes, allowing for better tracking of the transformation of raw materials into finished goods. Additionally, these systems facilitate comprehensive evaluation and analysis of yield, quality, and resource utilization, positioning manufacturers for success in a competitive landscape.

Ongoing innovations in fiber spinning technologies are expected to further enhance the texturization of plant proteins, catering to the increasingly discerning consumer. Furthermore, advancements in separation technologies are crucial for optimizing product recovery and ensuring high-quality outputs. Innovations in decanter centrifuges and centrifugal separators enhance separation efficiency while reducing energy consumption, thereby promoting more hygienic process management.

Customize My Report : https://www.meticulousresearch.com/request-customization/cp_id=5342

By focusing on reliability and longevity in equipment design, manufacturers can reduce downtime and improve throughput, ultimately enhancing facility capacity utilization. Emerging technologies such as 3D printing and shear cells hold potential for further advancements in production capabilities, positioning the industry for continued growth.

Contact Us:

Meticulous Research®

Email- sales@meticulousresearch.com

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research