The wood CNC router machine has transformed the woodworking industry, offering unparalleled precision, efficiency, and versatility. This advanced technology allows for intricate cuts and detailed designs on wood, making it an essential tool for both professional woodworkers and hobbyists. In this comprehensive guide, we will explore the features, benefits, and applications of wood CNC router machines, providing valuable insights for those looking to enhance their woodworking projects.

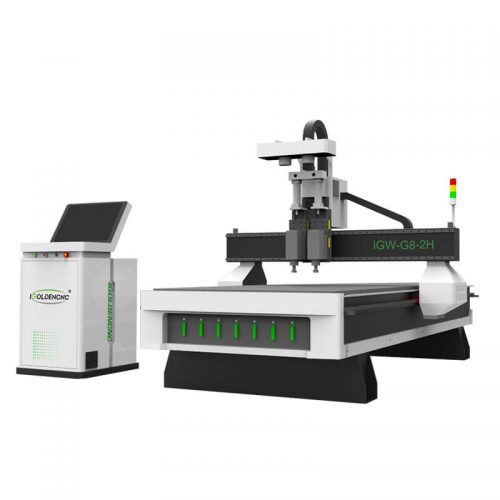

Wood CNC Router Machine

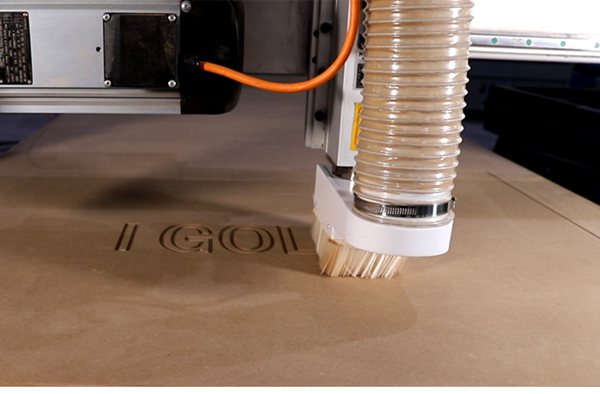

A wood CNC router machine is a computer-controlled device that uses a rotating cutting tool to carve, cut, and shape wood with high precision. The CNC (Computer Numerical Control) system automates the cutting process, allowing for complex and detailed designs that are difficult to achieve with manual methods.

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories.

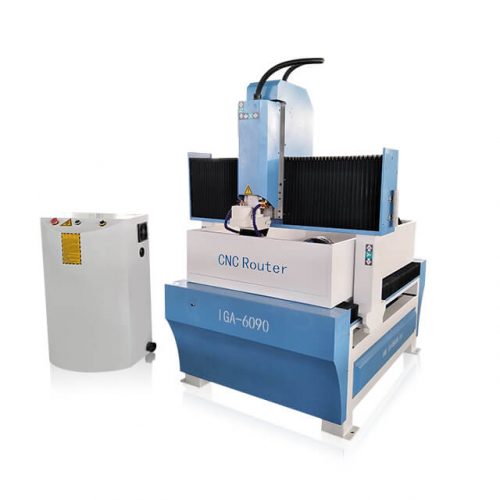

The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. The most used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft.

A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations. Whether you are a craft carpenter or a professional woodworker, you can easily find your next CNC router at IGOLDENCNC to automate your woodworking projects. Its user-friendliness, ease of use and multi-function make it easy for you to benefit and profit. Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

3 axis Wood CNC Router Machine

3 axis Wood CNC Router Machine

4 axis Wood CNC Router

5 axis Wood CNC Machine

Advantages of Wood CNC Router Machines

Precision and Accuracy

One of the most significant advantages of Wood CNC router machines is their precision and accuracy. Traditional woodworking methods rely heavily on manual labor, which can lead to inconsistencies and errors. CNC routers, however, are controlled by computer software, allowing for precise and repeatable cuts. This ensures that each piece is identical, which is crucial for mass production and intricate designs.

Efficiency and Speed

CNC routers significantly increase efficiency and speed in woodworking. These machines can operate continuously without fatigue, unlike human workers. They can process multiple parts simultaneously, reducing production time. Additionally, CNC routers can quickly switch between different cutting tools and operations, further enhancing productivity.

Versatility

Wood CNC router machines are highly versatile and can perform a wide range of operations, including cutting, engraving, drilling, and milling. They can handle various materials, such as hardwood, softwood, plywood, MDF, and even some plastics and composites. This versatility makes CNC routers suitable for diverse applications in different industries.

Cost-Effectiveness

Although the initial investment in a Wood CNC router machine can be substantial, the long-term cost savings are significant. CNC routers reduce material waste by optimizing cuts and minimizing errors. They also lower labor costs by automating repetitive tasks. Over time, these savings can offset the initial investment and lead to higher profitability.

Safety

CNC routers enhance safety in the workplace. Traditional woodworking tools can be dangerous, requiring close manual handling of sharp blades and cutting tools. CNC routers, on the other hand, operate within enclosed spaces and are controlled remotely via computer software. This reduces the risk of accidents and injuries, creating a safer working environment.

Customization and Flexibility

CNC routers offer unparalleled customization and flexibility. Users can easily modify designs and create custom pieces tailored to specific requirements. The ability to quickly change cutting parameters and tool paths allows for the production of unique and personalized items, catering to individual customer needs.

What Are CNC Wood Routers Used For?

These automatic machine tools are mostly used for woodworkers and carpenters to do woodworking in industrial manufacturing, small business, small shop, home business, home shop, school education. Besides, craftsman and hobbyists will also find a computer-controlled wood CNC machine useful.

Here are some of the fields where a CNC wood router will have access:

• Furniture Making: home furniture, art furniture, antique furniture, office furniture, cabinet making, door making, cabinet doors, interior doors, home doors, cupboard doors, table legs, sofa legs, wood spindles, corners, screens, headboards, composite gates, MDF projects, wood crafts, wood arts.

• Advertising.

• Die Making.

• Hollowing.

• Relief Carvings.

• Wood Cylinders.

• 3D Woodworking Projects.

• Sign Making.

• Custom Woodworking Plans.

How To Choose The Best Router Bits For Wood?

In woodworking, many details can affect the quality, accuracy and appearance of the final woodworking project, especially the selection of router bits for woodworking.

Choosing the right tool according to different processing materials and different machining processes is an important factor to ensure fast and efficient production.

-

CNC ROUTER, CNC WOOD ROUTER

CNC ROUTER, CNC WOOD ROUTERBest Wood CNC Machine for Small Business

-

CNC WOOD ROUTER

CNC WOOD ROUTERBest CNC Router Machines for Woodworking

-

CNC WOOD ROUTER

CNC WOOD ROUTERLatest 1325 Wood CNC Machine 4×8

-

CNC WOOD ROUTER

CNC WOOD ROUTERCNC Wood Router Manufacturers and Supplier

-

3 AXIS CNC ROUTER, CNC WOOD ROUTER

3 AXIS CNC ROUTER, CNC WOOD ROUTER3 Axis CNC Router with automatic tool changer

-

HOT

3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER

3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER3 Axis ATC CNC Router with Automatic Tool Changer for Wood Furniture

-

HOT

3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER

3 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERWood 3 Axis 4*8 CNC Router Machine for Sale

-

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERMulti Use 4 Axis Woodworking CNC Router with Rotary Axis

-

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER4 Axis CNC Wood Engraving Machine with Spindle Swing 180 Degree

-

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTER

3D CNC ROUTER, 4 AXIS CNC ROUTER, CNC ROUTER, CNC WOOD ROUTERRotary Spindle 4 Axis CNC Wood Engraving Machine with Auto Tool Change

-

HOT

4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTER

4 AXIS CNC ROUTER, CNC FOAM CUTTER, CNC ROUTER, CNC WOOD ROUTER4 Axis Machining Centre CNC Milling Machine for Foam, Aluminum, Wood Mold Processing

ATC CNC ROUTER SERIES

ATC CNC router is the first choice for enterprises with large production volume. According to the different tool changing methods, automatic tool changing engraving machines can be subdivided into linear ATC CNC machine and disc ATC engraving machines.Compared with the traditional manual tool change production method, this type of ATC CNC engraving machine has an independent tool magazine with different tool bits.

Atc CNC Router Wood Carving Machine with Pinch Roller

CNC WOOD ROUTER SERIES

With the features of low cost, simple operation and easy maintenance, this CNC wood router is considered an entry-level machine in the CNC machine industry and favored by users at home and abroad. The CNC wood router mainly performs some plane processing on the board. If you are just doing flat machining on some plates, this three-axis engraving machine is definitely your ideal choice.

Of course, if you have other machining requirements such as three-dimensional work pieces, curved surface machining of complex work pieces, we also have CNC equipment such as 4-axis CNC machine, rotary axis CNC machine, ATC CNC machine and multi-head engraving machine for you to choose.